In a bold step toward sustainable innovation, Breezy, a key player in the refurbishment and remarketing of second-life IT products, has unveiled its groundbreaking Industry 5.0 production line in Raszyn, Poland. This cutting-edge facility, a subsidiary of the ASBIS Group, harnesses the power of artificial intelligence and robotics to transform the way pre-owned smartphones are graded and upgraded. With the capacity to assess up to one million devices annually and refurbish over 320,000, the compact 600 m² plant represents a significant leap forward in precision and efficiency for the re-commerce industry.

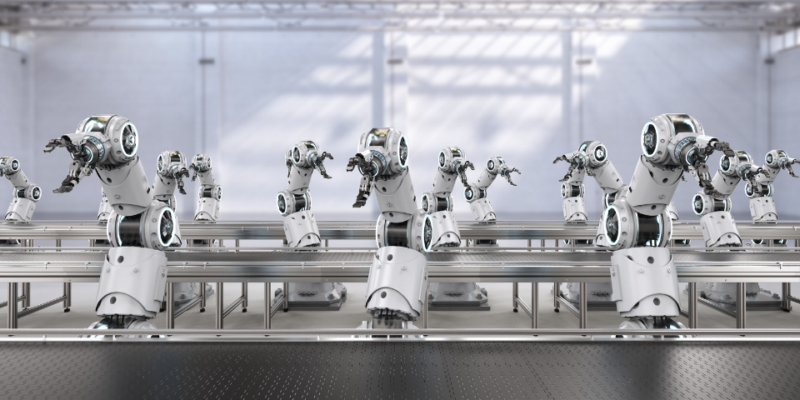

The facility’s advanced grading and sorting system is a marvel of modern engineering. Featuring 18 robotic workstations and requiring minimal human oversight, the process begins with an automated DECANT station that identifies device models, IMEI, and serial numbers while ensuring data erasure complies with stringent NIST-800-88 standards. Devices are then charged, connected to a diagnostic application, and prepared for a series of AI-powered inspections. These include visual detection of scratches, robotic audio tests in soundproof chambers, and automated evaluations of touch functionality, buttons, and cameras. This meticulous process ensures each device is accurately assessed for cosmetic or technical refurbishment needs.

Transparency and sustainability are at the core of Breezy’s operations. Following inspections, devices are photographed from six angles in an automated booth, with images instantly added to their digital portfolios for buyer assurance. The final stages involve data erasure, eco-friendly packaging, and labeling tailored to specific markets. By integrating advanced robotics and AI, Breezy’s Raszyn facility not only enhances the efficiency of device refurbishment but also sets a new benchmark for environmentally conscious practices in the tech industry. This pioneering initiative underscores the company’s commitment to driving sustainability while delivering high-quality, second-life products to consumers worldwide.

Serhei Kostevitch, CEO of ASBIS Group, stated that he is pleased “…to witness the outcome of the collaborative efforts between Breezy’s re-commerce experts and the ASBIS Robotic Solutions (AROS) engineering team. Their partnership has resulted in the establishment of a cutting-edge, ‘Industry 5.0’ automated production facility. This scalable and cost-effective solution ensures consistent diagnostics and can be replicated cost-effectively across multiple markets.” Likewise, Emil Oklinski, Director of Breezy Poland, commented that “AI and robotic solutions enable 24/7 operations, scaling, grading and upgrading to 1,000,000 units per year with improved accuracy. Breezy is also prepared to offer device grading as a service, ensuring compliance with a range of data protection standards.”

To recall, Industry 5.0 represents a transformative shift toward sustainability, resilience, and a human-focused approach, emphasising the harmonious collaboration between people and advanced technologies. At Breezy’s state-of-the-art facility, robotic systems and AI-driven automation handle repetitive and labor-intensive tasks, freeing employees to focus on higher-value activities like repairs and customer engagement, enhancing both productivity and job satisfaction. This model not only supports environmental goals by extending the lifespan of devices, minimising electronic waste, and significantly lowering carbon emissions, having already saved over 20,000 tons of CO2-equivalent by refurbishing more than 300,000 smartphones, but also strengthens business adaptability in the face of evolving market demands. By streamlining operations, reducing errors, and optimising costs, Breezy ensures competitive pricing and profitability while fostering consumer confidence through transparent and detailed product insights, setting a new benchmark for the circular economy.

Andrii Kosar, General Manager of Breezy, finally stated that: “One of Breezy’s core values is transparency, which we achieve by providing customers with maximum product information before they even open the box of a refurbished device. Thanks to automated photography, we capture high-quality images from six angles, revealing the finest exterior details. Additionally, each product carries a QR code linking to a certification report detailing over 55 testing parameters. Our automated grading system enables this unique level of transparency for our customers and will markedly improve our scalability, sustainability, and time-to-market..”